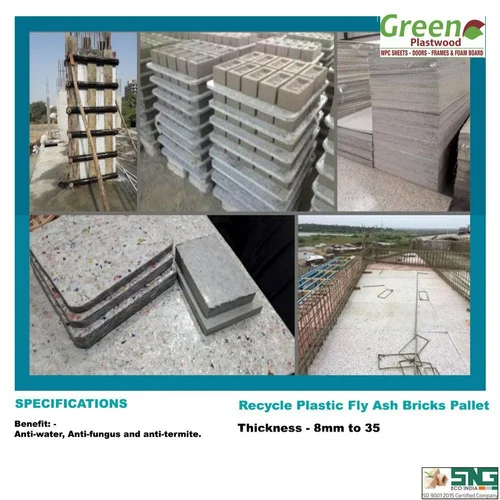

Waterproof Plastic Bricks Pallets

75.00 INR/Square Foot

Product Details:

- Usage Commercial

- Material Fly Ash Bricks Pellets

- Size Customize

- Product Type Waterproof Plastic Bricks Pallets

- Thickness 8/12/15/18/20/22/24/25/30/35 MM Millimeter (mm)

- Color White

- Surface Treatment Polished

- Click to View more

X

Waterproof Plastic Bricks Pallets Price And Quantity

- 75.00 INR/Square Foot

- 100 Square Foot

Waterproof Plastic Bricks Pallets Product Specifications

- Ageing Resistant

- White

- Polished

- Fly Ash Bricks Pellets

- Commercial

- Customize

- 8/12/15/18/20/22/24/25/30/35 MM Millimeter (mm)

- Waterproof Plastic Bricks Pallets

Product Description

Waterproof plastic bricks pallets are specialized pallets designed to withstand exposure to water and moisture during the production, storage, and transportation of bricks. These pallets are made from waterproof and durable plastic materials, providing excellent resistance to water absorption, mold, rot, and degradation. They offer numerous benefits, including enhanced durability, improved product quality, and reduced maintenance costs.

Frequently Asked Questions (FAQ):

Q: What are waterproof plastic bricks pallets made of?

A: Waterproof plastic bricks pallets are typically made from high-quality plastic materials, such as polyethylene (PE) or polypropylene (PP). These plastics are engineered to be waterproof, ensuring excellent resistance to water absorption and degradation.

Q: Are waterproof plastic bricks pallets compatible with brick-making machinery?

A: Yes, waterproof plastic bricks pallets are designed to be compatible with standard brick-making machinery. They are available in various sizes and configurations to fit accurately within the brick molds, facilitating efficient production processes.

Q: Can waterproof plastic bricks pallets be recycled?

A: Depending on the type of plastic used, waterproof plastic pallets can be recyclable. Many manufacturers use recyclable plastics, such as PE or PP, which can be recycled into new plastic products at the end of their lifespan. Local recycling facilities and regulations should be consulted for proper disposal and recycling options.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

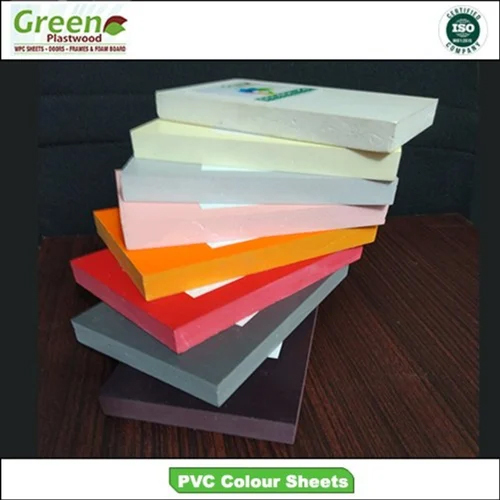

Other Products in 'PVC Solid Sheet / Board' category

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese